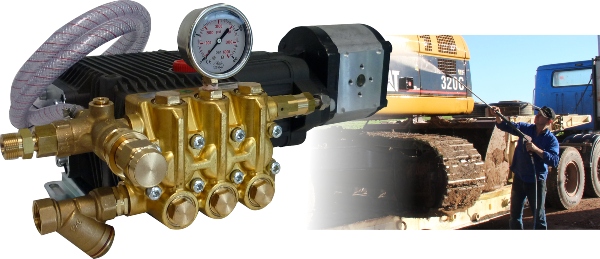

A comprehensive range of high pressure wash down kits designed for mobile plant has been released by Australian Pump Industries. The kit is based on “Big Berty” Bertolini heavy duty, Triplex pumps. These pumps are equipped with gear drive mounted hydraulic motors for ease of installation on plant.

“We got the inspiration from tanker operators installing both hydraulic drive high pressure blasters and dust suppression self-priming water pumps at the same time. Running these off the hydraulic system of the prime mover offers huge advantages in terms of convenience and cost.” said John Hales, Aussie Pumps’ Chief Engineer.

Big Berty pumps are famous for their reliability and are designed for a long, trouble free life. The pumps have solid ceramic pistons with many of the models are designed to run at 1,450 rpm, or even lower speed where required.

Best of all, the company has integrated the hydraulic motor through a heavy duty, fully enclosed drive. This ensures that the connection between the hydraulic motor and the Bertolini pump is completely dust free.

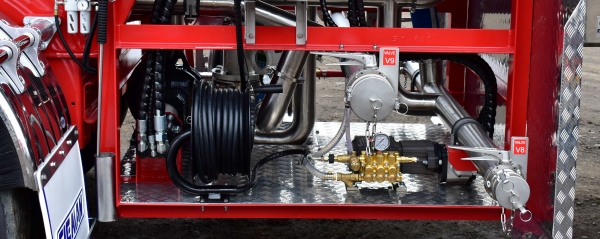

Installation in mobile plant is simple and easy. Hydraulic drive ensures flexible power transfer. This is from the PTO pump on the prime mover’s gearbox to the most convenient location on the vehicle!

‘Big Berty’ Bertolini pumps come with a unique four-year warranty. This is a first for this type of equipment and is an indication of Australian Pumps’ confidence in the brand.

Only first world hydraulic motors are used. The pumps water pressures range from 3,000 psi through to 5,000 psi. An additional option is Aussie’s stainless steel 5,000 psi rated hose reel with 30m of Aussie Blu-Pro hose already installed.

“Mounting the high pressure hose reel and gun holster close to the pump is the way to go,” said John Hales. “Many of these units are now being installed on the back of tankers to give the operator more range.”

All units come with a heavy duty brass inlet strainer with nipple and tap fitting to connect to a supply hose.

SAFETY FEATURES

Most importantly, the system also features Aussie’s ASP (Aussie Safety Protection) kit. This consists of an independent brass unloader valve. This controls the flow of water to the gun and a pressure gauge. A safety valve is also fitted. This releases excess pressure in the event of a pressure spike or if the unloader is adjusted higher than the factory pre-set.

A thermal dump valve is also installed as part of the kit. The thermal dump will protect the pump seals from excessive heat caused by extended bypass operation.

Aussie’s hydraulic driven pressure washers are already being installed on water carts on construction sites for plant cleaning. There are also major applications found on concrete pumps, garbage trucks, drill rigs, vac trucks and even trawlers, tugs and other work boats.

“A 2,000 psi, 27 lpm model, THY2715HYD, is proving popular in the earthmoving industry where the high flow and pressure combination gets plant cleaned fast.” said Hales.

A wide range of other options are available with the machine. This includes turbos, telescopic wands with up to 5.5m length and even foamers and drain cleaning kits.