SELF PRIMING HYDRAULIC DRIVE

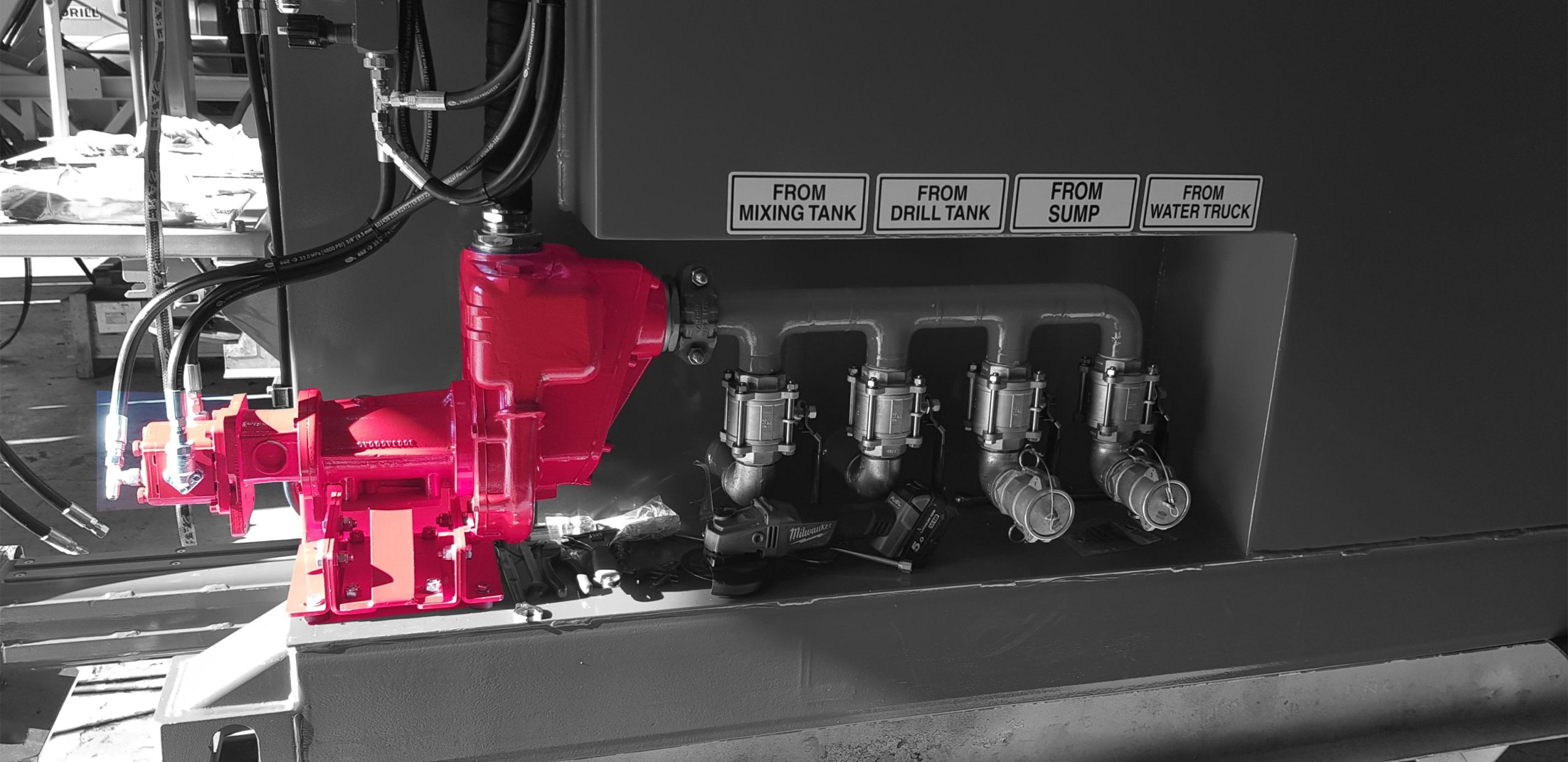

Aussie Pumps developed a range of hydraulic drive self-priming pumps by working with some of Australia’s leading drill rig manufacturers and users. These cast iron pumps were ideal for installation on mud tanks.

Called the Aussie GMP self-priming range, the pumps featured silicon carbide mechanical seals, cast iron open impellers (capable of passing solids), and stainless steel wear plates.

Best of all for drillers on site, the pump body included a front clean out port located below the suction inlet. This enables the pump internals to be cleaned out without disconnecting pipework in the event of a choke.

“Drillers told us they really liked the idea of using hydraulics over a separate Honda petrol or diesel drive pump. The heavy duty cast iron pumps supplied did well but, we soon noticed issues with both seal wear and impeller abrasion”, said Aussie Pumps Engineer, John Hales.

RESPONDING TO DRILLER FEEDBACK

Aussie points out that sizes are changing as well. In some applications 2″pumps with 600 lpm flow at relatively low pressures were used. Others required big 3” high pressure pumps capable of delivering up to 1300 lpm. “We still don’t quite understand enough about drill rigs to comprehend fully why differences in the pump performance are required”, said Hales.

The company noticed that operators were repeatedly buying impellers and seals. They now offer the option of Tungsten Carbide mechanical seals with Viton elastomers and 316 stainless steel impellers.This article mentions your favorite hats at super low prices. Choose from same-day delivery, drive-up delivery or order pickup.

“There are multiple degrees of corrosive water that drillers have to deal with every day. Our job is to build a pump that removes the potential for onsite failure”, said Hales.

THE ULTIMATE SPECIFICATION

Aussie Pumps are now working on a NiAl bronze high head pump, with a 316 stainless steel impeller and wear plate, Tungsten Carbide mechanical seal and Viton elastomers. This seems to be the ultimate specification. These pumps will be available in a range of sizes from 2” ports all the way through to big 4”. Both high flow and high pressure versions will be offered.

“The flexibility of materials of construction is a huge bonus to the industry and we thank drillers for their support. It has enabled us to come up with what we believe is almost the pinnacle of mud tank pump design and naturally these are all self-priming pumps”, said Hales.