Aussie Safety Protection

Aussie Safety Protection

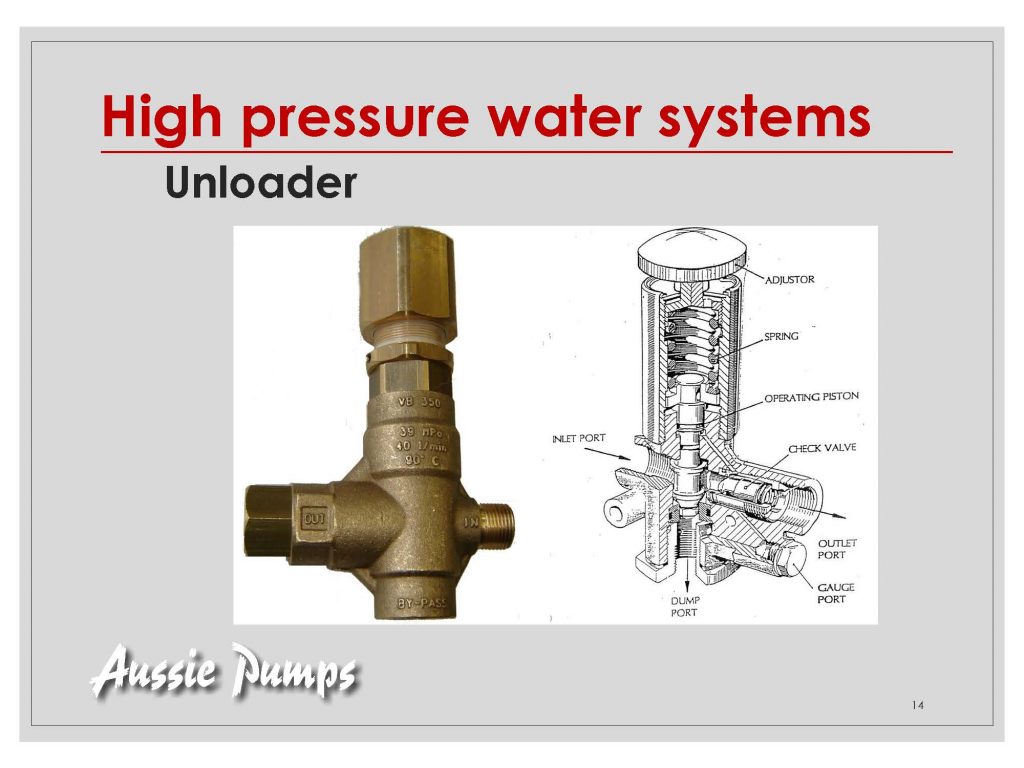

The unloader valve controls the pressure to the gun, and by-passes the water back through the pump or into a brake-tank when the gun trigger is closed.

This valve is set at the factory and should only be adjusted during a blaster service.

During normal operation, when the gun trigger is open, about 10% of the water flow should still be by-passed back to the pump to lubricate and cool the unloader.

The safety valve (left) protects the pump and operator from any pressure spikes. These can be caused if the unloader is worn, dirty or damaged.

The thermal dump valve (right) protects the pump seals if the pump is left running on by-pass for too long and the temperature of the water increases to above 60 degrees centigrade.

When the thermal dump activates, water from the pump is released to the ground, allowing cool water to enter. Once the temperature of the water drops the thermal dump valve will self reset.

This video shows the process of setting of the safety valve and unloader, and is shown here to give you understanding on how they work together. This process should only be carried out by a qualified technician.